Decoupled engine ancillary

Project Overview

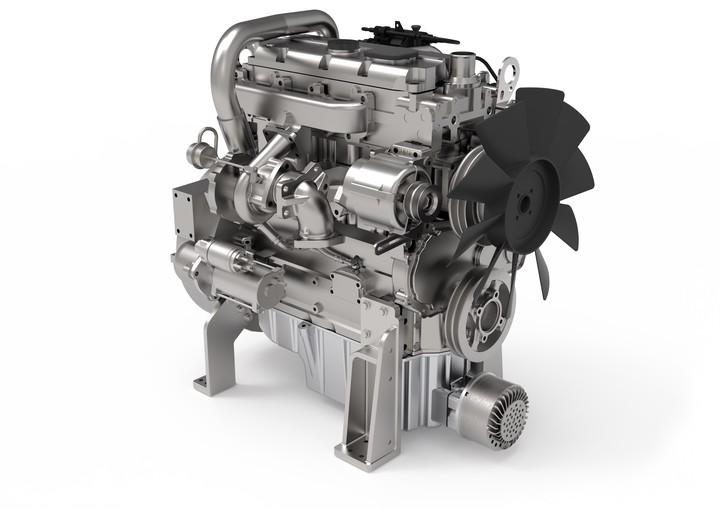

This project was conducted in collaboration with Perkins Engines, to develop a method of reducing engine losses through the decoupling of engine ancillaries. The coursework was done as a group project with four other team members. The dissertation summary is detailed below.

The pressure put on engine manufacturers due to the environmental impact of their combustion engines has become increasingly large. This has caused manufacturers to look away from increased power and load capacities, and towards improvements in efficiency and fuel savings. One method of achieving fuel savings is to assess the power draw from ancillary parts and how they could be better powered to save energy.

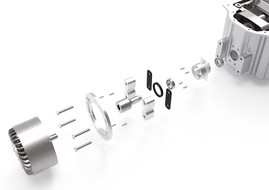

The engine ancillaries are predominantly made up of pumps that provide cooling, lubrication, and fuel flow to the engine. Each of the pumps is run off the engine’s crankshaft meaning that they are directly coupled to the engine. Although direct coupling indicates that the pumps are always running when the engine is, an increase in the pump’s requirement does not always match the increase in the engine’s speed. This is especially evident for the oil pump which provides engine lubrication that has its highest requirement at start-up.

The difference between the ancillary’s requirement and the engine speed means that the ancillary is over-working for the majority of the engine’s use. This means that there is scope to improve the engine’s efficiency by de-coupling the ancillaries so they can run optimally for the engine’s requirement.

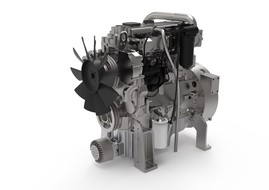

This project investigated the design and benefits that can be found from decoupling select ancillary components on a Perkins 1204 series, 4.4-litre diesel engine.